Collar sizes:

Drilling/collaring/trimming: Ø12–30 mm | O.D. ½”–1 1⁄8″

Elliptical pilot hole:Ø17,2–30 mm | O.D. ¾”–1 1⁄8”

Drilling/collaring: Ø6–28 mm | O.D. ¼”–1 1⁄8″

Run tube sizes: Ø8–30 mm | O.D. 5⁄16″–1 1⁄8″

Pipe material: Steel, Stainless steel, Aluminium, Copper, Copper-Nickel

Machine type: Industrial machines

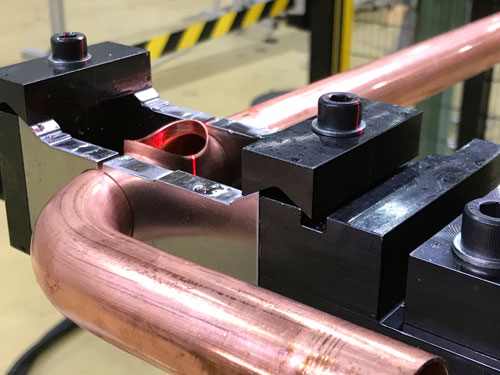

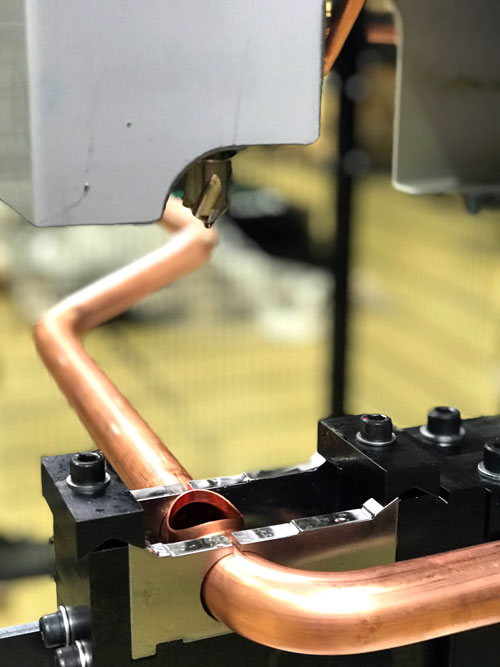

Process: Collaring

S-28 Collaring Machine for bent tubes

T-DRILL S-28 is a slim collaring machine that is designed especially for bent tubes with tight curves when collaring machine S-56 is not suitable.

S-28 is equipped with the newest technology, robust construction, and clamping. Accurate servo-controlled movements ensure the best possible collaring result.

S-28 is capable of producing collars for copper, aluminum, steel, stainless steel, brass, and other malleable materials. Collar sizes from 6 to 28 mm.

S-28 Collaring Machine

- Industry 4.0 ready machine: very versatile and easily customized to fit specific customer needs

- Designed for producing T-outlets for brazed and welded joints on both straight and bent tubes

- Collar sizes Ø 6 mm – Ø 28 mm

- User-friendly GUI interface with color touch panel

- Adjustable machining parameters & fine-tuning of motion profiles

- Easier welding (butt weld outlet vs nozzle weld)

Enables three types of processes:

- Drilling/collaring – Used for lap joint method

- Drilling/collaring/trimming – Used for butt weld method

- Elliptical pilot hole – Used for butt weld method. Elliptical pilot hole is done beforehand with laser, plasma, milling or with punching machine. Enables 1:1 collaring.

COMPARISON: Welded Fittings vs T-DRILL Collaring & Flanging